HEICO Aircraft Maintenance – a milestone for growth and efficiency.

We moved to our new facility

HEICO Aircraft Maintenance – a milestone for growth and efficiency.

The precise monitoring and maintenance of aircraft is essential for air traffic safety. As a continuously growing EASA, FAA, UK CAA Part-145 certified MRO service provider, we specialize in the repair of structural components and non-destructive testing (NDT) of components and aircraft structures of a wide range of aircraft types. Our state-of-the-art repair workshops are strategically located and are only a few minutes away from Leipzig Airport (LEJ), one of the largest cargo hubs in Europe. This means we can act quickly, flexibly and cost-effectively when carrying out repairs.

“We offer our customers a reliable and comprehensive service. In addition, our team has decades of experience in the repair of aircraft components made of sheet metal and fiber composites. This means that we are always able to offer individual repair solutions that are optimally tailored to specific customer needs. Whether in our workshop, on site at the customer or directly on the aircraft. Our mobile experts are there when they are needed.”

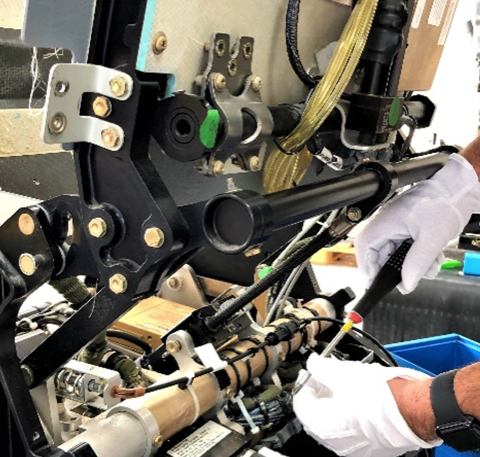

HEICO Aircraft Maintenance has a wide range of experience in the repair and overhaul of structural components made of sheet metal and fiber composites. Our highly specialized professionals place a special focus on high-end repair techniques and individual solutions for damage beyond the SRM/CMM limits.

For support inquiries please contact: +49 (0) 1713308013

Our cabin mechanics have a wide range of experience in the field of repair, modification and refurbishment of cabin components for a wide variety of aircraft types:

Please report: +49 (0) 1713308013

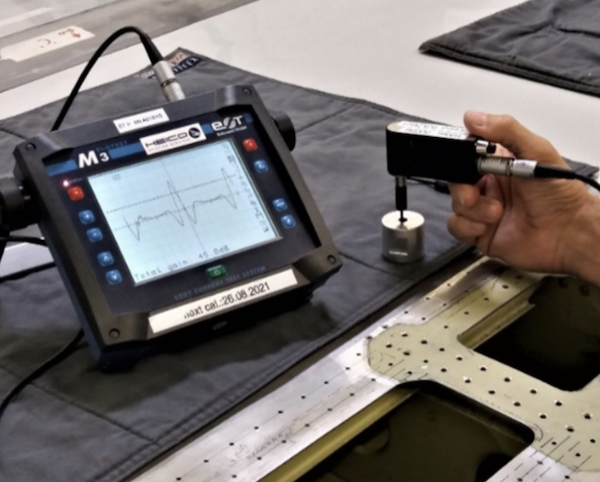

The HEICO Aircraft Maintenance NDT team works with the latest generation of test equipment. All inspections are performed by our highly experienced Level II technicians. Our range of NDT services:

Mehr Informationen: Download HEICO NDT flyer here.

For non-destructive testing, please contact: +49 (0) 1705616978

Training and further qualifications are very important to us so that our highly qualified specialist staff can continue to develop just as quickly as the complex technologies and materials in the aviation industry.

That is why we also rely on a successful and experienced partner for the qualification of our employees: Earth & Flight Composites Training & Consultancy (EFC). Their team has over three decades of advanced composites experience and conducts composite fabrication and repair training in a designated training area within our repair facilities.

We are qualified for the repair of structural components according to C1, C4, C6, C7, C8, C9, C14 and C20 - as well as the services for non-destructive testing of components and aircraft structures according to D1.

The starting signal for the construction of our new premises at Leipzig Airport was given about 2 years ago - we were now able to move. For seven years now, we have been working on-site with our specialists from eight nations for the repair of aircraft structural components and non-destructive testing of aircraft structures. Our MRO operation is located just a few minutes from Leipzig Airport (LEJ), one of the largest cargo hubs in Europe. Due to the positive development among our customers, especially in air freight, the number of aircraft to be serviced is constantly growing. We look forward to looking after our customers' various projects in our larger, modern home in 2024.

HEICO Aircraft Maintenance – a milestone for growth and efficiency.

HEICO Aircraft Maintenance – a milestone for growth and efficiency.

Serving the aviation industry at most major German airports.

Serving the aviation industry at most major German airports.

| EASA/ UK CAA rating | FAA rating (if relevant) | part number | Component/Assembly | Manufacturer | A/C type |

| C6 | Limited Airframe | 55709-105 | BALLMAT ASSEMBLY | AAR Cargo Systems | A300-600 |

| CO* | Limited accessories | 314T4210-77 | PW4000 ENGINE CORE COWL ASSEMBLY | Boeing | B767-300 |

| CO* | Limited Airframe | 113N4601-9 | SPOILER ASSY-NO.6 LH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4200-32 | SPOILER ASSY NO. 7RH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-30 | SPOILER ASSY NO. 7RH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4000-12 | SPOILER ASSY NO. 8RH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 114N4005-127 | WING LEADING EDGE SLAT NO. 4 | Boeing | B757-200 |

| CO* | Limited Airframe | 114N4005-116 | WING LEADING EDGE SLAT NO. 7 | Boeing | B757-200 |

| C20 | Limited Airframe | 149N7511-1 | PANEL ASSY | Boeing | B757-200 |

| CO* | Limited Airframe | 113W6600-1 | DOOR ASSY-COVE LIP DOOR FLAPERON WING TE | Boeing | B777-F |

| C6 | Limited Airframe | 415N0017-7SP | DOOR ASSY | Boeing | B757-200 |

| C20 | Limited Airframe | 143N5654-176 | PANEL ASSY | Boeing | B757-200 |

| C20 | Limited Airframe | A9232024200010 | RADOME ASSY | Airbus | A300-600 |

| C20 | Limited Airframe | 141A5810-181 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-507 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-59 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-520 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-528 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-130 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-189 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-459 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-465 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-468 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-142 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-144 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-155 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-157 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-158 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-16 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-16 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-160 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-16 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-516 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-168 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-175 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-176 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-183 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-186 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-188 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-246 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-261 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-266 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-268 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-292 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-31 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-44 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-449 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-459 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-46 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-52 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-526 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-53 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-558 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-559 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-56 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-560 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-561 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-562 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-736 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-737 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-738 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-747 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-766 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-767 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-768 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-98 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-1 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-100 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-101 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-12 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-123 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-13 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-131 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-132 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-133 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-134 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-135 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-144 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-145 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-146 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-147 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-148 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-19 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-22 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-23 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-26 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-27 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-31 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-33 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-34 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-37 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-39 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-4 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-41 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-42 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-43 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-5 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-511 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-512 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-513 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-514 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-515 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-167 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-517 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-519 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-521 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-523 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-524 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-525 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-526 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-529 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-530 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-531 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-533 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-534 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-60 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-61 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-67 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-68 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-8 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-82 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-86 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-90 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-92 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-96 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-97 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-98 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-99 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-122 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-123 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-124 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-125 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-126 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-127 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-128 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-129 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-131 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-132 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-15 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-159 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-166 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-165 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-17 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-18 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-19 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-21 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-22 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-23 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-48 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-49 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-7 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-8 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-9 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-100 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-102 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-103 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-104 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-105 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-108 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-109 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-12 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-13 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-164 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-19 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-20 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-21 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-22 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-25 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-26 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-28 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-29 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-31 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-32 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-34 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-35 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-36 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-4 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-453 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-454 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-456 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-457 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-460 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-461 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-462 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-464 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-469 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-471 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-5 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-54 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-6 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-7 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-71 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-73 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-8 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-9 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-99 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-132 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-136 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-137 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-163 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-17 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-18 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-19 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-20 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-21 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-23 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-27 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-28 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-29 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-30 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-344 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-345 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-40 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-23 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | F5331439501700 | PANEL ASSY | Airbus | A330-200 |

| C20 | Limited Airframe | F5331439502000 | PANEL ASSY | Airbus | A330-200 |

| C20 | Limited Airframe | F5331439501500 | PANEL ASSY | Airbus | A330-200 |

| C20 | Limited Airframe | F5331440000600 | PANEL ASSY | Airbus | A330-200 |

| C20 | Limited Airframe | F5331440000700 | PANEL ASSY | Airbus | A330-200 |

| C20 | Limited Airframe | F5331439501600 | PANEL ASSY | Airbus | A330-200 |

| C20 | Limited Airframe | 152W8601-75 | PANEL ASSY | Boeing | B777-F |

| C20 | Limited Airframe | 152W8601-66 | PANEL ASSY | Boeing | B777-F |

| C20 | Limited Airframe | 152W8701-43 | PANEL ASSY | Boeing | B777-F |

| C20 | Limited Airframe | D5367175500000 | PANEL FLOOR | Airbus | A318 / A319 / A320 / A321 |

| C20 | Limited Airframe | D5367161300000 | PANEL FLOOR | Airbus | A318 / A319 / A320 / A321 |

| C20 | Limited Airframe | D5361067500000 | PANEEL | Airbus | A318 / A319 / A320 / A321 |

| CO* | Limited Airframe | A5777101000600 | SPOILERS ASSY | Airbus | A300-600 |

| C20 | Limited Airframe | 313T3360-183 | TRAILING EDGE ASSY - LH SIDE | Boeing | B767-300 |

| CO* | Limited accessories | LJ76875 | COWL ASSY - TRANSLATING COWL AND BLOCKER FLAPS - LH | Boeing | B757-300 |

| CO* | Limited accessories | 221-4050-85 | INLET COWL | Pratt & Whitney | PW4000 / A300-600 |

| C20 | Limited Airframe | A5327996200200 | PANEL FLOOR | Airbus | A300-600 |

| CO* | Limited Airframe | 114N1603-17 | PANNEL ASSY - LH WING LE | Boeing | B757-200 |

| CO* | Limited Airframe | 114N1604-12 | WING FIXED LEADING EDGE SKIN | Boeing | B757-200 |

| C20 | Limited Airframe | 144A5810-150 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-151 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-149 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-157 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-155 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-156 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-153 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-190 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-161 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 144A5810-162 | PANEL ASSY | Boeing | B737-800 |

| C6 | Limited Airframe | A2557561100200 | PANEL SIDEWALL | Airbus | A300-600 |

| C6 | Limited Airframe | 453W1710-101 | PANEL ASSY SLOPED CLG | Boeing | B777-F |

| CO* | Limited Airframe | 114N2103-22 | PANEL ASSY - WING LE | Boeing | B757 |

| CO* | Limited Airframe | 114N4005-157 | SLAT ASSY-NO. 4 | Boeing | B757-200 |

| CO* | Limited Airframe | 113W2700-13 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 183N2003-1 | ELEVATOR ASSY-LH | Boeing | B757-200 |

| CO* | Limited Airframe | 149N6002-70 | DOOR ASSY MLG | Boeing | B757-200 |

| C20 | Limited Airframe | A5796564000251 | FAIRING ASSY-FIXED, FLAP TRACK 5 - LH SIDE | Airbus | A300-600 |

| C20 | Limited Airframe | A5357505200000 | FAIRING ASSY-VERTICAL ROD, FWD - LH SIDE | Airbus | A300-600 |

| CO* | Limited Airframe | A5527605600051 | ELEVATOR ASSY-Z345 RH | Airbus | A300-600 |

| CO* | Limited Airframe | 113N7100-74SP | AILERON ASSY-RH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | A5766100117400 | AILERON ASSY-ALL SPEED - LH SIDE | Airbus | A300-600 |

| CO* | Limited Airframe | A5777150000200 | SPOILERS ASSY | Airbus | A300-600 |

| CO* | Limited Airframe | A5771007600600 | SPOILERS ASSY-N1-N2 | Airbus | A300-600 |

| C20 | Limited Airframe | A5357000800400 | FIN ASSY-DORSAL | Airbus | A300-600 |

| CO* | Limited Airframe | 189N0001-17 | TIP ASSY - LH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | A5517127000001 | TIP ASSY-THS, Z332 (LH) | Airbus | A300-600 |

| CO* | Limited Airframe | A5517876000000 | EDGE ASSY LEADING, CENTER (LH) | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000000351 | FLAP ASSY INNER - RH SIDE | Airbus | A300-600 |

| CO* | Limited accessories | LJ71568 | PANEL HINGED COWLING - RH SIDE | RR/Boeing | RB211-535C Series / 757-200 |

| CO* | Limited accessories | LJ35910 | COWL ASSY-FULLY EQUIPPED NOSE | RR/Boeing | RB211-535 / 757-200 |

| CO* | Limited accessories | LJ71942 | C DUCT ASSY | RR/Boeing | RB211-535C Series / 757-200 |

| CO* | Limited Airframe | 114N2107-16 | PANEL ASSY - WING LE | Boeing | B757-200 |

| CO* | Limited Airframe | 114N2108-12 | PANEL ASSY - WING LE | Boeing | B757-200 |

| CO* | Limited Airframe | 114T3100-35 | SLAT ASSY - NO. 6 | Boeing | B767-300 |

| C6 | Limited Airframe | 232N1709-48 | PANEL ASSY | Boeing | B757-200 |

| C20 | Limited Airframe | F7XC536010101 | PANEL 134AR ASSY | HENCE | Falcon 7X |

| C20 | Limited Airframe | F7XC536010103 | PANEL 134AR ASSY | HENCE | Falcon 7X |

| C20 | Limited Airframe | F7XC536010107 | PANEL 134AR ASSY | HENCE | Falcon 7X |

| C20 | Limited Airframe | F7XC536010109 | PANEL 134AR ASSY | HENCE | Falcon 7X |

| C20 | Limited Airframe | F7XC536010101S1 | PANEL 134AR ASSY | HENCE | Falcon 7X |

| C20 | Limited Airframe | 119N0003-6 | WING TIP - ACCESS DOOR RH | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4000-11 | SPOILER ASSY NO. 5 - LH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5100-31 | SPOILER ASSY NO. 1, 2, AND 3 - LH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5100-32 | SPOILER ASSY NO. 10, 11 AND 12 - RH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5501-10 | SPOILER ASSY NO. 10, 11 AND 12 - RH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5501-5 | SPOILER ASSY NO. 1, 2 AND 3 (WINGS ONLY) - LH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5501-6 | SPOILER ASSY NO. 10, 11 AND 12 (WINGS ONLY) | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5501-9 | SPOILER ASSY NO. 1, 2, AND 3 - LH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5601-23 | SPOILER ASSY NO. 4 - LH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5601-31 | SPOILER ASSY NO. 4 - LH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5601-34 | SPOILER ASSY NO. 9-RH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5501-23 | SPOILER ASSY NO. 1, 2, AND 3 - LH SIDE | Boeing | B737-800 |

| CO* | Limited Airframe | 114N4002-132 | SLAT ASSY-NO. 10 WING LE | Boeing | B757-200 |

| CO* | Limited Airframe | 114N4003-171 | SLAT ASSY-NO. 2 WING LE | Boeing | B737-800 |

| CO* | Limited Airframe | 114N4004-165 | SLAT ASSY-NO. 3 | Boeing | B757-200 |

| CO* | Limited Airframe | 114N4005-132 | SLAT ASSY-NO. 7 WING LE | Boeing | B737-800 |

| CO* | Limited Airframe | 114N3002-19 | SLAT ASSY-NO. 5 | Boeing | B757-200 |

| CO* | Limited Airframe | 114N3002-20 | SLAT ASSY-NO. 6 | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-2 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-5 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | A5527605600091 | ELEVATOR ASSY-RH | Airbus | A300-600 |

| CO* | Limited Airframe | 183N2003-24 | ELEVATOR ASSY-RH SIDE | Boeing | B757-200 |

| CO* | Limited Airframe | 116W2604-15 | PANEL ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 116W2617-15 | PANEL ASSY | Boeing | B737-800 |

| CO* | Limited Airframe | A5517704800300 | PANEL ASSY-ACCESS NO 4 RH | Airbus | A300-600 |

| C20 | Limited Airframe | A5327996300200 | PANEL FLOOR | Airbus | A300-600 |

| CO* | Limited Airframe | 113A3700-19 | FLAP ASSY-AFT, OUTBD TE FLAP | Boeing | B737-800 |

| C6 | Limited Airframe | 5209-10 | DOGHOUSE | Innovint | B737-800 |

| CO* | Limited accessories | 314N3010-25 | INLET ASSY | Pratt & Whitney | B737-800 |

| CO* | Limited Airframe | 114N3002-63 | SLAT ASSY-NO. 5 | Boeing | B757-200 |

| CO* | Limited Airframe | D5537002601000 | PANEL LEADING EDGE 2 | Airbus | A320 |

| CO* | Limited accessories | UL29906 | Fairing Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 116W2610-21 | Panel 511 AB | Boeing | B777-F |

| C20 | Limited Airframe | A2557158700200 | PANEL FLOOR | Airbus | A300-600 |

| C20 | Limited Airframe | A2557157300200 | PANEL FLOOR | Airbus | A300-600 |

| CO* | Limited Airframe | 114A1110-18 | Leading edge Kruger flap 4 | Boeing | B737-800 |

| CO* | Limited Airframe | 114A1110-17 | Leading edge Kruger flap 1 | Boeing | B737-800 |

| C20 | Limited Airframe | A5327996100200 | PANEL FLOOR | Airbus | A300-600 |

| C20 | Limited Airframe | A2557158800000 | PANEL FLOOR | Airbus | A300-600 |

| CO* | Limited Airframe | 114A5030-207 | Slat #3 | Boeing | B737-800 |

| CO* | Limited Airframe | 114A5040-208 | Slat #5 | Boeing | B737-800 |

| CO* | Limited Airframe | 114N4005-188A | Slat #7 RH | Boeing | B737-800 |

| CO* | Limited Airframe | 113N1712-51A | Fairing Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 141W5350Y4 | DOOR ASSY | Boeing | B737-800 |

| CO* | Limited Airframe | 146W6612-6 | DOOR ASSY | Boeing | B737-800 |

| CO* | Limited Airframe | F5237120001400 | Cover Assy - Access | Airbus | A300-600 |

| CO* | Limited Airframe | 113T2201-27 | Flap Assy -Main- LH | Boeing | B737-800 |

| CO* | Limited Airframe | 114A1220-7 | Leading edge Kruger flap 2 | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-129 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-511 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-479 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-235 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-567 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-489 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-147 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-488 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-169 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-160 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-122 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-159 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-189 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-448 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-105 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-143 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-304 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-38 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-121 | PANEL ASSY | Boeing | B737-800 |

| CO* | Limited Airframe | 141W5350-4 | DOOR ASSY | Boeing | B777-200 |

| CO* | Limited Airframe | 113N2800-61 | FLAP ASSY INBD TE AFT LH | Boeing | B757-200 |

| CO* | Limited Airframe | A5527605500095 | ELEVATOR ASSY-LH | Airbus | A300-600 |

| CO* | Limited Airframe | 114N4003-153 | SLAT #2 LH | Boeing | B757-200 |

| C6 | Limited Airframe | A2557546600400 | Panel Assy decompression | Airbus | A300-600 |

| C6 | Limited Airframe | A2557430100000 | Panel Assy decompression | Airbus | A300-600 |

| C20 | Limited Airframe | 148T7702-01 | Tail skid fairing | Boeing | B767-300 |

| C20 | Limited Airframe | CMKD8400FP-519 | Floor panel | Bombardier | DHC-8-400 |

| C20 | Limited Airframe | CMKD8400FP-518 | Floor panel | Bombardier | DHC-8-400 |

| C20 | Limited Airframe | CMKD8400FP-513 | Floor panel | Bombardier | DHC-8-400 |

| CO* | Limited Airframe | 116W2610-26 | Panel 611 AB | Boeing | B777-F |

| C20 | Limited Airframe | 453W5211-267 | Floor panel | Boeing | B777-F |

| CO* | Limited Airframe | A5517127000100 | TIP ASSY-TRIMMABLE HORIZONTAL STABILIZER | Airbus | A300-600 |

| CO* | Limited Airframe | 113A3700-24 | FLAP ASSY-AFT, OUTBD TE FLAP | Boeing | B737-800 |

| C20 | Limited Airframe | 353N4014-5 | Bellmouth Assy | Boeing | B757-300 |

| CO* | Limited accessories | 353N2002-2 | APU inlet duct | Boeing | B757-300 |

| CO* | Limited Airframe | 110A0113-5 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-6 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-9 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-10 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-11 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-12 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-13 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-14 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-15 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-16 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-17 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-18 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-19 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-20 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-21 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-22 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-23 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-24 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-25 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-26 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-27 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-29 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-30 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-31 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-32 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-33 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-34 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-35 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-36 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-37 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-38 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-39 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-40 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-41 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-42 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-43 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-44 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-45 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-46 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-47 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-57 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-58 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-63 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-64 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-65 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-66 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-69 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 110A0113-70 | Door Assy | Boeing | B737-800 |

| CO* | Limited Airframe | 65-25326-710 | Door Assy Main Cargo | Boeing | B757-200 |

| C20 | Limited Airframe | 314-2100-4 | INLET COWL | Boeing | B737-800 |

| CO* | Limited Airframe | 114N1523-1 | PANEL ASSY | Boeing | B757-200 |

| C6 | Limited Airframe | A2577186001200 | BALLMAT | Airbus | A300-600 |

| CO* | Limited Airframe | 141N6920-26 | DOOR ASSY NLG AFT RH | Boeing | B757-200 |

| CO* | Limited Airframe | 141N6920-25 | DOOR ASSY NLG AFT LH | Boeing | B757-200 |

| C20 | Limited Airframe | 141A5810-303 | PANEL ASSY | Boeing | B737-800 |

| C6 | Limited Airframe | 70744-401-001 | Seat Assy | Brice | |

| C6 | Limited Airframe | 70743-401-001 | Seat Assy | Brice | |

| C6 | Limited Airframe | 70744-411-001 | Seat Assy | Brice | |

| C6 | Limited Airframe | 70743-411-001 | Seat Assy | Brice | |

| CO* | Limited accessories | 221-4050-513 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-27 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-29 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-31 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-47 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-49 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-509 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-48 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-511 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-515 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-521 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-523 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-525 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-53 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-57 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-63 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-65 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-67 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-69 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-71 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-75 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-79 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-83 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-87 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-88 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-89 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-90 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited accessories | 221-4050-91 | INLET COWL | Pratt & Whitney | PW4000 |

| CO* | Limited Airframe | 65-25326-10 | Door Assy Main Cargo | Boeing | B757-200 |

| CO* | Limited Airframe | 65-25326-18 | Door Assy Main Cargo | Boeing | B757-200 |

| CO* | Limited Airframe | 65-25326-22 | Door Assy Main Cargo | Boeing | B757-200 |

| CO* | Limited Airframe | 65-25326-703 | Door Assy Main Cargo | Boeing | B757-200 |

| CO* | Limited Airframe | 65-25326-705 | Door Assy Main Cargo | Boeing | B757-200 |

| CO* | Limited Airframe | 65-25326-708 | Door Assy Main Cargo | Boeing | B757-200 |

| CO* | Limited accessories | 224-2302-545 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224-2302-517 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224M4761-517 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224-2302-521 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224M4761-521 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224-2302-523 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224M4761-523 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224-2302-525 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224M4761-525 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224-2302-527 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224M4761-527 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224-2302-529 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224M4761-529 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224-2302-531 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224-2302-537 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224M4761-537 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224-2302-539 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224M4761-539 | Core Cowl R/H | Boeing | B767-300 |

| CO* | Limited accessories | 224-2301-513 | Core Cowl L/H | Boeing | B767-300 |

| CO* | Limited accessories | 224-2301-521 | Core Cowl L/H | Boeing | B767-300 |

| CO* | Limited accessories | 224M4761-513 | Core Cowl L/H | Boeing | B767-300 |

| CO* | Limited Airframe | A5796000000051 | FLAP ASSY L/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000000151 | FLAP ASSY R/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000000251 | FLAP ASSY L/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000000451 | FLAP ASSY R/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000000551 | FLAP ASSY R/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000000651 | FLAP ASSY L/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000000751 | FLAP ASSY R/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000000851 | FLAP ASSY L/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000000951 | FLAP ASSY R/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000001051 | FLAP ASSY L/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000001151 | FLAP ASSY R/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000001251 | FLAP ASSY L/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000001351 | FLAP ASSY R/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000001451 | FLAP ASSY L/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5796000001551 | FLAP ASSY R/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5786320115000 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786320115100 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786320115400 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786320115500 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786320115600 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786320115700 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325115000 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325115100 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325115400 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325115500 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325115600 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325115700 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325115800 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325115900 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325116000 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325116100 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325116200 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325116300 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325116400 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325116500 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325116600 | SLAT ASSY No.1 | Airbus | A300-600 |

| CO* | Limited Airframe | A5786325116700 | SLAT ASSY No.1 | Airbus | A300-600 |

| C20 | Limited Airframe | 757-0010-6 | Winglet R/H | Boeing | B757-300 |

| C20 | Limited Airframe | 757-0010-4 | Winglet R/H | Boeing | B757-300 |

| C20 | Limited Airframe | 757-0010-3 | Winglet L/H | Boeing | B757-300 |

| C20 | Limited Airframe | 757-0010-5 | Winglet L/H | Boeing | B757-300 |

| CO* | Limited Airframe | 148T7702-1 | TAIL SKID FAIRING | Boeing | B767-300 |

| CO* | Limited Airframe | 113N2003-36 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-1 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-10 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-13 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-14 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-15 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-16 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-17 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-19 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-20 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-21 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-22 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-23 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-24 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-25 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-26 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-27 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-28 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-29 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-3 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-31 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-32 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-33 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-34 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-35 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-39 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-4 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-41SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-42SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-43SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-44SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-45SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-46SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-47SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-48SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-49SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-50SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-51SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-52SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-53SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-54SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-55SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-56SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-57SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-58SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-59SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-6 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-60SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-63SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-64SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-66SP | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-7 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-8 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2003-9 | FLAP ASSY-INBD TE MAIN | Boeing | B757-200 |

| C20 | Limited Airframe | 113N1982-18 | Aileron PCU Access Door R/H | Boeing | B757-200 |

| CO* | Limited Airframe | A5517610000002 | TIP ASSY THS, Z332 L/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5517610000001 | TIP ASSY THS, Z332 L/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5517127000201 | TIP ASSY THS, Z332 L/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5517127000101 | TIP ASSY THS, Z342 R/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5517127000301 | TIP ASSY THS, Z342 R/H | Airbus | A300-600 |

| CO* | Limited Airframe | A5517610000102 | TIP ASSY THS, Z342 R/H | Airbus | A300-600 |

| CO* | Limited Airframe | 113N2100-1 | CARRIAGE ASSY-INBD MAIN FLAP INBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2100-4 | CARRIAGE ASSY-INBD MAIN FLAP INBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2100-6 | CARRIAGE ASSY-INBD MAIN FLAP INBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2100-8 | CARRIAGE ASSY-INBD MAIN FLAP INBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2100-11 | CARRIAGE ASSY-INBD MAIN FLAP INBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2100-13 | CARRIAGE ASSY-INBD MAIN FLAP INBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2100-17 | CARRIAGE ASSY-INBD MAIN FLAP INBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2100-20 | CARRIAGE ASSY-INBD MAIN FLAP INBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-1 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-4 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-7 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-9 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-17 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-21 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-2 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-5 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-8 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-10 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-18 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113N2150-22 | CARRIAGE ASSY-INBD MAIN FLAP OUTBD ASSEMBLY | Boeing | B757-200 |

| CO* | Limited Airframe | 113W2700-1 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 113W2700-10 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 113W2700-14 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 113W2700-17 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 113W2700-18 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 113W2700-2 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 113W2700-21 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 113W2700-22 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 113W2700-5 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 113W2700-6 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 113W2700-9 | FLAP ASSY | Boeing | B777-F |

| CO* | Limited Airframe | 113N1910-6 | Fairing AFT R/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N1910-18 | Fairing AFT R/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N1910-5 | Fairing AFT L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N1910-17 | Fairing AFT L/H | Boeing | B757-200 |

| C20 | Limited Airframe | 141A5810-748 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-729 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-227 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-749 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-750 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-249 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-735 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 141A5810-739 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-569 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-570 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-571 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-572 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-547 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-548 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-518 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-537 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-551 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-538 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-539 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-540 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-556 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-541 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-557 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-527 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-559 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-560 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-561 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-563 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-564 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-565 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-566 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-535 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 143A5810-568 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-472 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-516 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-455 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-478 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-491 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-492 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-493 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-494 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-495 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-496 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-497 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-498 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-499 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-501 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-481 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-482 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-483 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-484 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-485 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-486 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-466 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-487 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-488 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-489 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-470 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 146A5810-490 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-422 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-423 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-440 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-439 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-444 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-398 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-411 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-421 | PANEL ASSY | Boeing | B737-800 |

| C20 | Limited Airframe | 147A5810-443 | PANEL ASSY | Boeing | B737-800 |

| CO* | Limited Airframe | D5757065000000 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000095 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000100 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D57570650000195 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000200 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000295 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000300 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000395 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000400 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000495 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000500 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000595 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000600 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000695 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000700 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000795 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000800 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000895 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000900 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065000995 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001000 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001095 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001100 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001195 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001200 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001295 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001300 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001395 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001400 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001495 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001500 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001595 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001600 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001695 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001700 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001795 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001800 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001895 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001900 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065001995 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002000 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002095 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002100 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002195 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002200 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002295 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002300 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002395 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002400 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002495 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002500 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002595 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002600 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002695 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002700 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002795 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002800 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002895 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002900 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065002995 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003000 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003095 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003100 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003195 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003200 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003295 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003300 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003395 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003400 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003500 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003600 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003700 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003800 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065003900 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065004000 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065004100 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065004200 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065004300 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065004400 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065004500 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065004600 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065004700 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065004800 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065004900 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065005000 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065005100 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065005200 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065005300 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065005400 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065005500 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065005600 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065005700 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065005800 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | D5757065005900 | FLAP ASSY INBOARD | Airbus | A320-200 |

| CO* | Limited Airframe | A5777100000800 | SPOILER | Airbus | A300-600 |

| CO* | Limited Airframe | A5777100000200 | SPOILER | Airbus | A300-600 |

| CO* | Limited Airframe | A5777100000400 | SPOILER | Airbus | A300-600 |

| CO* | Limited Airframe | A5777100001000 | SPOILER | Airbus | A300-600 |

| CO* | Limited Airframe | A5777101000400 | SPOILER | Airbus | A300-600 |

| CO* | Limited Airframe | 114W4150-7 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-9 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-11 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-13 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-15 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-17 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-19 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-21 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-23 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-25 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-27 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-101 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-29 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-31 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-103 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-33 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-105 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-37 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-107 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-39 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-109 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-41 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 654W0006-211 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-111 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-113 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-115 | SLAT ASSY #5 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-8 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-10 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-12 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-14 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-16 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-18 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-20 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-22 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-24 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-26 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-28 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-102 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-30 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-32 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-104 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-34 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-106 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-38 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-108 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-40 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-110 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-42 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 654W0006-210 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-112 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-114 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 114W4150-116 | SLAT ASSY #10 | Boeing | B777-F |

| CO* | Limited Airframe | 113N5000-17 | SPOILER ASSY NO: 1, 2, 3 L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5000-19 | SPOILER ASSY NO: 1, 2, 3 L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5501-35SP | SPOILER ASSY NO:1, 2, 3 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5501-45SP | SPOILER ASSY NO:1, 2, 3 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5501-43SP | SPOILER ASSY NO:1, 2, 3 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5501-39SP | SPOILER ASSY NO:1, 2, 3 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5501-37 | SPOILER ASSY NO:1, 2, 3 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5501-47SP | SPOILER ASSY NO:1, 2, 3 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5601-29SP | SPOILER ASSY NO. 4 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5601-5 | SPOILER ASSY NO. 4 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5400-45 | SPOILER ASSY NO:. 4L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5000-27 | SPOILER ASSY NO:. 4L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5000-25 | SPOILER ASSY NO:. 4L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5601-9 | SPOILER ASSY NO. 4 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5601-33SP | SPOILER ASSY NO. 4 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5601-37SP | SPOILER ASSY NO. 4 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5601-39SP | SPOILER ASSY NO. 4 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N5601-41SP | SPOILER ASSY NO. 4 (WING ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4100-39 | SPOILER ASSY NO. 5L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4000-13 | SPOILER ASSY NO. 5L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4501-29SP | SPOILER ASSY NO. 5 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4501-27SP | SPOILER ASSY NO. 5 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4501-25SP | SPOILER ASSY NO. 5 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4501-23SP | SPOILER ASSY NO. 5 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4501-13SP | SPOILER ASSY NO. 5 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4501-19 | SPOILER ASSY NO. 5 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4501-5 | SPOILER ASSY NO. 5 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4501-1 | SPOILER ASSY NO. 5 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-35A | SPOILER ASSY NO. 6 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-33A | SPOILER ASSY NO. 6 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-31A | SPOILER ASSY NO. 6 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-29A | SPOILER ASSY NO. 6 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-35SP | SPOILER ASSY NO. 6 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-33SP | SPOILER ASSY NO. 6 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-31SP | SPOILER ASSY NO. 6 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-29SP | SPOILER ASSY NO. 6 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-23 | SPOILER ASSY NO. 6 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-5 | SPOILER ASSY NO. 6 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-36A | SPOILER ASSY NO. 7 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-34A | SPOILER ASSY NO. 7 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-32A | SPOILER ASSY NO. 7 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-30A | SPOILER ASSY NO. 7 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-36SP | SPOILER ASSY NO. 7 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-34SP | SPOILER ASSY NO. 7 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-32SP | SPOILER ASSY NO. 7 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-30SP | SPOILER ASSY NO. 7 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-24 | SPOILER ASSY NO. 7 (WINGS ONLY) L/H | Boeing | B757-200 |

| CO* | Limited Airframe | 113N4601-10 | SPOILER ASSY NO. 7 (WINGS ONLY) L/H | Boeing | B757-200 |